What Is Knit Fabric? Warp Knit & Weft Knit

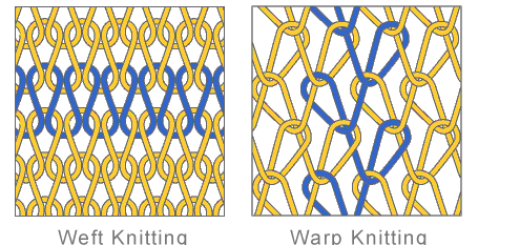

Knit fabric. It is the staple in the fabric industry and we wanted to learn more and share with you all about knit fabric. In the textile fabric industry, fabrics can be created by two processes, warp knitting and weft knitting. Weft and warp knitting are two different knitting techniques that result in various types of fabrics. The main way to distinguish the two types is that weft knitting has the yarn run back and forth while warp runs the yarn up  and down. This difference can create two entirely different end products. Weft knitting can produce shaped and drapeable fabrics while warp knitting produces more coarse yardage.

and down. This difference can create two entirely different end products. Weft knitting can produce shaped and drapeable fabrics while warp knitting produces more coarse yardage.

Weft Knitting

This technique uses a continuous thread to form courses and loops in the fabric. Weft knitting is when yarn runs horizontally, from side to side, across the width of the fabric. Fabric begins to form by manipulating the knitting needles to create loops horizontally that build on top of each other (see picture). This one continuous thread makes the fabric creates an incredibly elastic fabric. This knitting process will many types of fabrics like jersey, rib, purl, jacquard, and interlock fabrics.

Characteristics of this fabric include:

- Very elastic

- Warm to wear

- Comfortable

- Different properties can be achieved depending on the yarns used

- Does not fray

- Various patterns can be achieved

- Good insulator

Warp Knitting

Warp knitting represents the fastest method of producing fabric from yarns. This differs from weft knitting in that each needle loops its own thread and runs vertically down the fabric. Warp knit fabrics will have the knit stitch on the face of the fabric but have a horizontal zigzag pattern on the back. As you may remember, this style of knitting creates like our Tricot and Raschel Knit fabrics.

Characteristics of this fabric include:

- Less elastic than weft knitting

- More run resistant than weft knitting

- Denser than weft knitting

- Type and weight of yarn dictates the type of fabric that is produced

- Warm to wear

- Comfortable

- Usually soft

- Good drape

- Easy to sew

Knitting Machines

The knits are on two types of machines: a circular knitting machine and a flatbed machine. The circular knitting machine is the first choice for manufacturers. Due to its productivity and user-friendliness, it is widely used throughout the industry to produce fabric and has a much large output capacity than the flatbed. The knitting needles of this machine are in a circular formation. In this case, the yarn feeds directly into the needle bed that spins around in one direction and creates a tube of fabric through the center.

A circular knitting machine is able to produce very fine structures due to the gentle nature of the knitting process. The diameter of the machine will vary depending on the type of fabric being made but it has a limited diameter range compared to its counterpart. Once the circular knits are created, the fabric can be cut open along the entire length to become the flat fabric we all know.

Flatbed knitting machines meanwhile are when knitting needles are in a flat, straight line. This produces the fabric that is in its open width, lying flat. This also has a large range in diameter depending on the end use of the fabric. More often than not, this machine produces fabric more slowly than the circular machine. However, this machine can create thicker fabrics and has more pattern design options than the circular machine.

1 Comment

-

Great summary, I always wondered what warp and weft meant!!