Whether you’re crafting a standout bikini or designing a performance swimsuit, choosing the right swimwear fabric matters. Here’s a refined guide from Pine Crest Fabrics’ textile experts on selecting swimsuit materials that balance performance, durability, comfort, and style.

What Material Is Used for Swimsuits

Most high-quality swimwear fabrics are made from nylon or polyester blended with spandex (elastane), combining stretch, durability, and comfort. Today, many of these fibers are also available in recycled versions, offering the same performance benefits with a smaller environmental footprint.

Nylon blends are known for their soft, smooth feel, excellent stretch and recovery, and lightweight comfort. These properties make nylon an ideal material for form-fitting swimwear like bikinis, one-pieces, and performance swimsuits. It also provides durability, abrasion resistance, and chemical resistance—a top choice for swimwear designers. Recycled nylon offers all the same benefits while supporting more sustainable production practices.

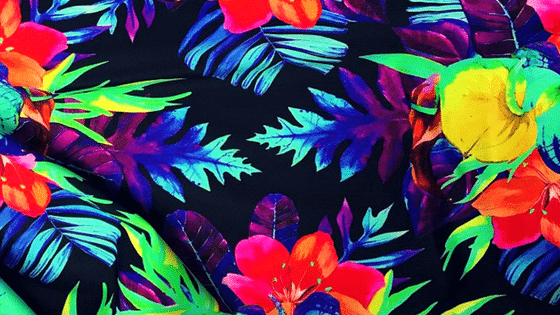

Polyester blends offer exceptional shape retention, UV and chlorine resistance, and vibrant colorfastness, especially useful for printed swimwear. Polyester fabrics are quick drying and easy to care for, making them great for both casual and high-performance swimwear designs. Recycled polyester delivers the same high performance and is widely used in sustainable swimwear collections across the industry.

Here is a comparison between nylon and polyester used for swimwear.

| Property | Nylon-Spandex Blends | Polyester-Spandex Blends |

|---|---|---|

| Stretch & Fit | Excellent stretch with soft hand feel; ideal for tight-fitting swim styles | Good stretch and structure; slightly firmer feel |

| Durability | High strength and abrasion resistance; resistant to rot and mildew | High strength and abrasion resistance; great wrinkle and crease resistance |

| Water Absorption & Drying | Low water absorption; quick drying | Very low moisture absorption; quick drying |

| Color Retention | Good color retention, ideal for neon or fluorescent colors | Excellent colorfastness and UV resistance |

| Chemical Resistance | Resistant to many chemicals and chlorine | Very resistant to chlorine, lotions, and sunscreen |

| Care & Maintenance | Requires moderate care | Easy care; wrinkle-resistant and durable |

| Print Quality | Softer finish, ideal for digital direct or wet printing in vivid, highly saturated colors | Superior for sublimation printing; holds vibrant color |

| Sustainability Options | Available in recycled forms (e.g., MIPAN regen) | Widely available as recycled polyester (e.g., REPREVE®); more colorfast |

What You Need to Know to Select Quality Swimwear Textiles

A quality swimwear fabric should retain its shape and color while withstanding regular exposure to saltwater, chlorine, and sun. Here are the key properties to look for:

- Durability: A quality swimwear fabric must withstand chlorine, salt water, sunlight, and contact with lotions and oils without fading, losing shape, or degrading. Look for materials that provide chlorine resistance, UV protection, fade resistance, and resistance to creams and oils. Collections like PCF’s Kira, Colorlock, Palm, and Orion are good examples.

- Stretch & Recovery: To fit close to the body, swimwear materials need four-way stretch (horizontal + vertical) and excellent recovery so they bounce back after wear, swimming, and movement.

- Quick Drying & Moisture Management: Fabrics that stay wet can irritate skin, cause odor, and degrade faster. Moisture-wicking finishes or fabrics that naturally shed water speed drying and improve comfort.

Why Are Most Swim Fabrics Synthetic

Synthetic fibers offer superior performance—quick drying, resilience, durability, shape retention, and stretch. Natural fibers like cotton, wool, or silk absorb water, dry slowly, lose their shape, and degrade more quickly when exposed to chlorine and UV rays, making them less suitable for swimwear. Historically, swimsuits were often made from knitted wool, which became heavy when wet, stretched out easily, and felt bulky to wear.

Can Foil Fabrics be Used for Swimwear?

Foils work well for fashion swimwear designed for wading, light swimming, and poolside lounging. However, it’s important to ensure the foil finish is durable (won’t crack), properly bonded, and compatible with the fabric’s elasticity; otherwise, it may peel or distort when exposed to water and stretch. Here are some of our foil fabrics, suitable for swimwear. At Pine Crest Fabrics, we offer third-party testing on select foil fabrics to verify how many pool hours the foil can withstand.

Are Swimwear Fabrics Sustainable and Safe?

Fabrics made from recycled materials like Repreve®, MIPAN regen® could be considered sustainable. Make sure you choose eco-certified fabrics with renowned certification systems such as GRS (Global Recycled Standard), OEKO-TEX, and bluesign. These materials are produced in alignment with sustainable principles and do not contain harmful chemicals.

How to Care for Nylon and Polyester Swimwear Fabrics

Proper care is essential for maintaining the stretch, color, and performance of swimwear materials.

Share these care tips with your consumers to keep swimwear garments looking and performing their best:

- Rinse after use: Try to rinse swimwear with cool, fresh water after swimming to remove chlorine, salt, and sunscreen that can break down fibers.

- Machine wash gently: Use a delicate cycle with cold or warm water (30-40°C / 104°F depending on the fabric) and a mild detergent. Avoid fabric softeners and bleach, which can damage elasticity and color.

- Air dry: Skip the dryer—high heat can degrade spandex and fade colors.

By following these steps, you can extend the life of your nylon or polyester swimwear fabrics and preserve their stretch, color, and shape—especially important for high-performance or fashion-forward designs.

Where to Buy Quality Swimwear Materials

Look for suppliers that offer small sample yardage (e.g., 1–2 yards), partner with renowned fiber brands like Repreve®, Creora® HighClo™, and XLANCE®, and provide transparent performance data (GSM, stretch %, UV rating, chlorine resistance), fabric certifications, and reliable customer support. Prioritize suppliers whose stocked fabrics you can swatch and test before committing.

Recommendations for Swimwear Designers

- Request fabric swatches and test them under real conditions (wet, stretched, exposed to sun and lotion) before placing large orders.

- Check if the fabric offers 4-way stretch and retains its recovery after repeated use.

- Fabrics with renowned certifications prove safety and sustainability.

- Look into care instructions and labeling—swimwear that is easy to care for increases customer satisfaction.

- Provide transparency in your product descriptions (fiber content, care, certifications) to help your customers and improve online search performance.

Want to learn more about quality swimwear materials for your next collection? Contact Pine Crest Fabrics—our fabric specialists, with over 20 years of experience in the textile industry, are here to guide you to the best materials on the market.